All clients are our good friends, we never lost a client once we started working together. Because of Factory Price, High Quality and Excellent Service. Please see below:

1.Quick responds: With HUAXU you deal directly with the decision maker, not wait for someone higher up and most everything is done in-house.

One point of contact from feasibility to delivery with program managers, who all have the experience and mold manufacturing background to provide complete support, to respond you immediately and Offer more professional comments.

2.One Stop Shop: For free, we will evaluate your designs for manufacturability, and communicate with your designers to improve and ensure ideal result. Besides normal mold design, manufacturing, molding, we also make silkscreen, spray-paint and assembly in house. It saves a lot.

3.High Quality: ISO90001/ISO14000 certified management system factory, with advanced CNC and SODICK EDM macking machines and CMM ( Coordinate Measuring Machines)to control the quality. Best solution base on 30+ years' experience engineers team in mould industry. Highly-skilled mould designer, engineers, toolmakers and inspectors handle your project from start to finish, ensuring optimal results.

4.Personalized Service: We treat every customer as friends in a respectful, trustworthy and knowledgeable manner, and always stand on customer’s position to think and provide perfect service. We build and run only first class molds. Just provide us with a part drawing, and we’ll provide you with a finished product.

5.Reasonable Factory Price: HUAXU is a middle size mold making and injection molding company, responsibility system management and all years qualified workers to make sure the efficiency, quality and cost.

Our Mission: To provide customers with Quality molded products and services while surpassing every customer expectations of production Quality, on-time delivery and reasonable price. Huaxu will achieve profitable growth as a problem solver as an industry leader, to be professional, trustworthy and creative toolmaker and injection molding supplier, we always keep Layout at the top level, introduce modernized management system, Go in for zero default. Make sure quality and techniques in the highest way. we dedicate to make innovation and progress continually to be your best partner in mold building, injection molding, print and paint, etc.

Huaxu Precision Tech is a private company founded in Shenzhen China 1995, with more than 300 workers 10,000 square meter plant, serving for the industries of Automotive, Electronics, Industrial, Medical and Packing.

We focus on Mould Making and offer full services for product developing, the mainly service are:

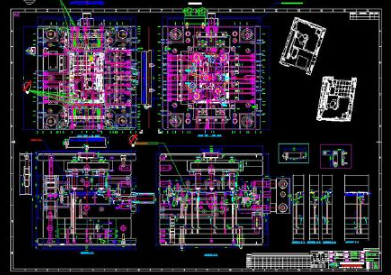

·Mould design

·Mould making

·Injection molding

·Secondary operation

·Precision machining

·Rapid prototyping

We have strong engineering support for CAD design and cost control for mould manufacturing. Our talented staff of sales, engineers, managers, and mouldmakers is dedicated to superior service and quality.

From your idea and drawings to the first fully qualified part, Huaxu Mold has the engineering expertise to design a working mold, shoot the initial shots, optimize the parameters then provide First Article Inspection Reports. If required PPAP and CPK data will be provided.

From your idea and drawings to the fully qualified part, Huaxu experienced designers and project managers will assist you with your product’s development cycle to shipping, to provide advice of design for manufacture, mould flow analysis, optimized solution also for assembly and packing, that maybe save millions of dollars on your manufacturing costs...

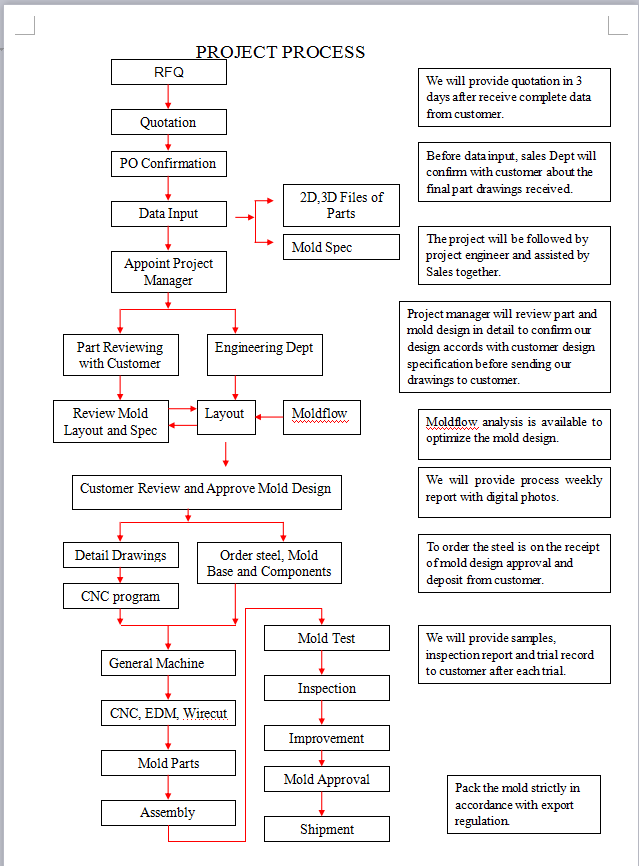

Base on final part drawing, DFM and mould drawings approved, we begin to build the tooling and prepare the first trial samples which typically occurs within a 3-5weeks. After samples to check and confirm with final components no problem by customer, mass production will be done soon...

ISO9001/ISO14000 certificates issued factory, Huaxu was in strict accordance with ISO9001 version of the requirements of full participation, continuous improvement, to achieve customer satisfaction, to ensure higher efficient, lower re-work rate, lower wastage, short delivery term from materials incoming to finished products output. All moulds and parts are inspected on site by QC team, and will final check again before shipping. We have precision CMM, height gage and so on to make sure all items in spec...

Per customer requirement, final 2D/3D product data, customer mold standard and specification will be followed in mould design. We will provide product optimized solution to suit injection moulding.

Detailed schedule will be provided and followed by our project manager, about critical control in design, tool machining, mold trials, production and delivery. Any professional comments or issues will be positive feedback at the first time to avoid mistake in future.

Shenzhen Huaxu Precision Tech ltd

Mobile: +86 18682199853

E-mail: alice@hua-xu.cn

Skype: alicema-mould

QQ: 997848477

Contact: Alice Ma( Ma Aifen)

Copyrights © 2017 All Rights Reserved Shenzhen huaxu precision technology Limited